Subdivided Installations

The subdividing of larger empty conduits or ducts should be considered in situations where there is a limited number of additional conduits/ducts to meet current or future optical fiber expansion, or where there may be specific permitting issues regarding additional optical fiber capacity.

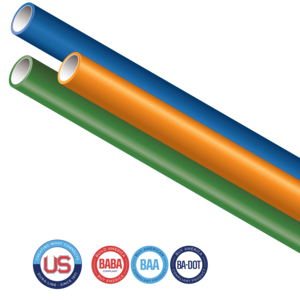

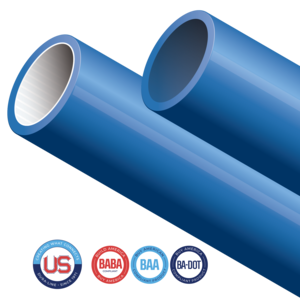

HARDWARE FOR PULLING IN ADDITIONAL HDPE DUCTS

It is essential to use the proper pulling hardware and not to exceed the maximum tensile pull rating of the ducts being placed. The use of swivels – attached to each duct and the lead pull line – and staggered wire rope slings (bridles) are necessary to allow maximum pulling clearance in the conduit and reduce or eliminate twisting of the multiple ducts during placement. Either threaded pulling eyes or wire mesh grips are attached to the duct(s). When placing different size ducts simultaneously, the pull tension maximum is limited to the duct with lowest published pull tension maximum.

PLACING OF MICRODUCT FOR SUBDIVIDING CONDUITS

For subdividing HDPE conduits (typically 1” to 2” ID), individual MicroDucts can be pulled in or air jetted (air-assist pushed) into the empty duct. Use proper pulling or jetting lubricants for better installation results.

For larger conduits, the use of FuturePath is more practical. Single or multiple FuturePath bundles in similar or differing tube-count configurations can be pulled in using conventional pulling hardware, including swivels, wire mesh grips, and staggered wire rope slings. Following placement, use clear push-fit couplers to join the MicroDucts at all access locations.