MicroTrench Installations

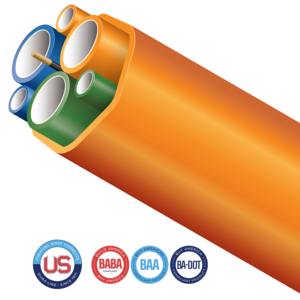

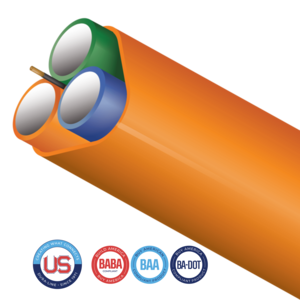

A more recent advancement in trenching involves cutting a sawcut trench or groove to be occupied by a variety of MicroDucts, either loose or bundled. FuturePath Flex allows for minimal trench width while also being able to be ‘rolled’ into a somewhat tubular shape for pulling purposes.

For more information on MicroTrenching, please visit Dura-Line's Technology Summit 2019: MicroTrenching.

Our Digital Tools are designed to aid you in choosing MicroTechnology products for specific installations.

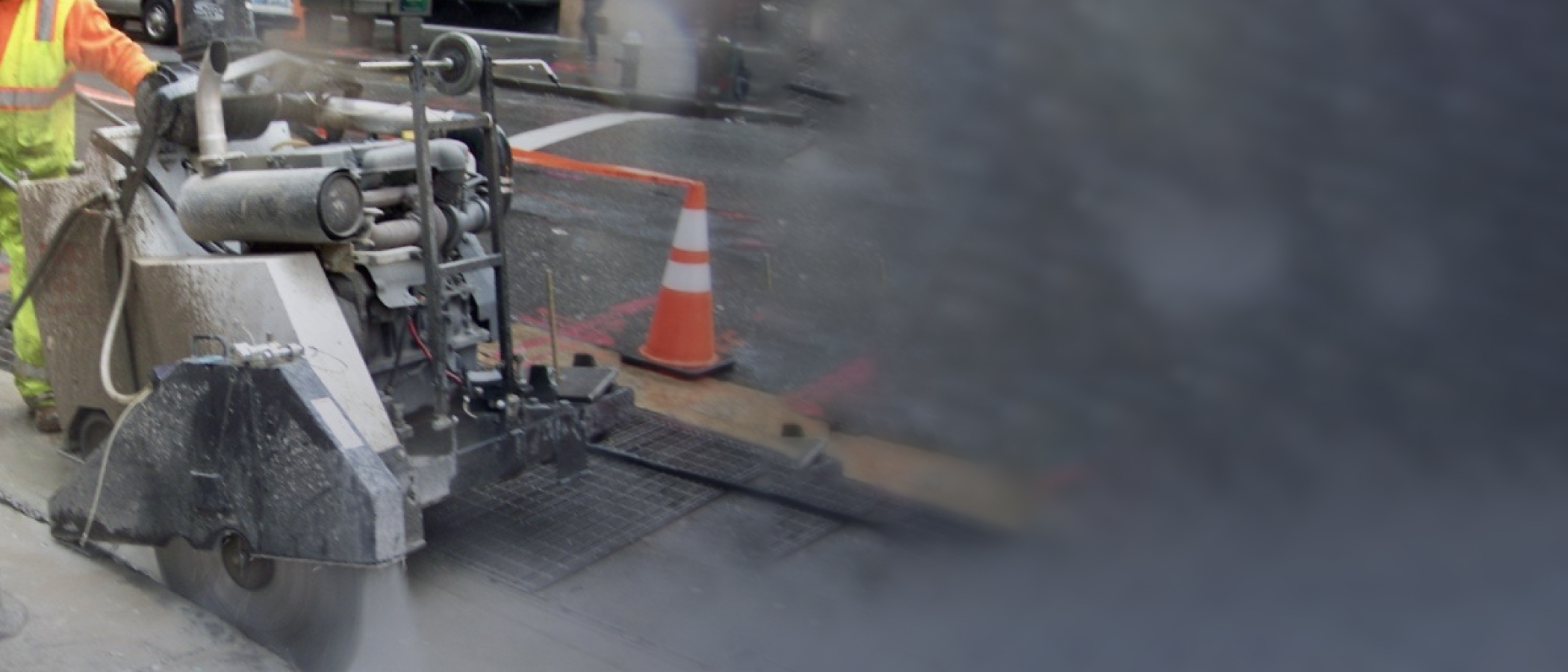

USING A MICROTRENCHER

MicroTrenching equipment uses specialized units to create precise depth/width micro-trenches. The type of road surface will dictate which equipment is best suited for the construction. Careful consideration has to be given as to the location of tie-ins (handholes, vaults) that are in line, or adjacent to, the MicroTrench. Collection of the trench spoils is required.

REINSTATING THE MICROTRENCH

Following the proper installation of the ducts or MicroDucts in the MicroTrench, the reinstatement sealing process is very critical since many of the asphalt materials are very hot (210°F to 300°F). Thus, the ducts may require a sand-based or foam backer rod heat barrier. Newer flowable grout materials generate little or no heat but will require proper preparation of the duct and MicroTrench and require specialized installation equipment and trained personnel.