CHALLENGE

Rocky Ground in a Remote Area

HUNTSVILLE, ONTARIO – both a vacation spot and year-round community deep in the Canadian Shield – has residents that want to maintain the tranquility of their remote, low-density setting while remaining connected to the rest of the world. But rocky terrain and many lakes and rivers make expanding broadband infrastructure a challenge.

SOLUTION

A Streamlined Aerial Build with MicroTechnology from Dura-Line

LIKE ALL DEPLOYMENT METHODS, aerial comes with its own unique challenges. Snow and ice loading, which add extra weight to poles, present concerns for any installer, particularly in cold, snowy regions like Ontario.

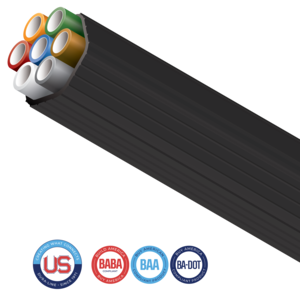

But in situations like Young’s, where aerial was the only choice, conduit provided distinct advantages over aerial cable alone by minimizing the risks of overloading the poles. Young chose to jet a 144-count micro cable into FuturePath Aerial 2-Way 12.7/10 mm, which provided a second pathway for the added benefit of scaling up as demand grows.

Young and his crew along with Dura-Line’s jetting experts and sales staff jetted 890 meters of 6.3mm, 144-count fiber cable through their FuturePath Aerial 12.7/10 with a 63% fill ratio and average speed of 70 meters per minute. Despite the varied and challenging terrain, the cable installation process took just 13 minutes.

Although this was new territory for Young and many other installers, he noted that his concerns were put to rest by the exceptional quality and performance of FuturePath from Dura-Line.

“Initially we were concerned about it potentially having ‘memory’ because it was flat. One really nice feature we found as we’re learning to deploy the MicroDuct in the air is that it installed just the same as if it was a traditional fiber or coaxial cable. In fact, we had left it outside in sub-freezing temperatures and it paid off the reel with no memory at all – it laid flat, and we lashed it with no problems.”

FuturePath Aerial allows the conduit’s full fiber capacity and maximum pole loading potential to be calculated once, at the very start of the deployment process. The additional pathway means that that the majority of the costs of permitting, leasing, and make-ready are also only incurred at the beginning.

“The beauty of this product is that we’ve done it once and we have the spare pathway, so we don’t have to go through any of that process again,” Young notes.

“It’s for the future – if we do have to get that second cable across that river, we’re not going through TransCanada waterway permitting again, we’re not going through all the permitting for the poles, et cetera, because it’s already been maxed out for the size of the bundled duct and then we can just jet that second fiber through.”

While aerial is still an emerging deployment method in Canada, Young’s experienced crew needed no specialized equipment or training to successfully execute the installation beyond what is standard for utility installations – this meant no additional time or cost was required for retraining.

And with support from Dura-Line, Young had access to expert hands-on technical support whenever needed. Dura-Line’s sales staff and field application engineers worked with Young and his crew during every stage of the project – from planning to installation and beyond – to ensure the smoothest execution possible.

RESULTS

A Smooth Installation, and a Live Network with No Need for Future Pole Loading Calculations

WITH A TEAM OF EXPERIENCED EXPERTS from his crew and Dura-Line, Young’s conduit and cable went up without a hitch, and is now live serving the Huntsville community. This innovative deployment method has potential for widespread application throughout low-density areas and challenging terrains, and the other stakeholders involved in the project are now interested in replicating the success of the project elsewhere.

Young is also planning for future use of his empty MicroDuct pathway in future builds. It’s there when required, but Spy won’t need to spend for it until it’s ready to be used, which means significant savings in terminating and testing every fiber – especially in light of future innovation as optical cables continue to get more fiber-dense.

When demand for service eventually does increase, Spy will be able to make upgrades without any further pole loading considerations. Where lashed aerial cable requires extensive and complicated calculations for any upgrades, the multiple pathways of FuturePath Aerial can be accounted for with one set of calculations at the point of installation.

And because of its uniform shape, FuturePath Aerial won’t have the small spaces that hold onto ice and catch wind as with overlashing. These complex considerations – often a headache for aerial installers – can now be frontloaded, and the additional fiber simply jetted in when needed.

“One of the exciting aspects of working with Dura-Line on this project was all the different types of expertise that came together on this job – aerial, underground, lashing, and jetting experts – having everyone working together as one team meant we were able to collaborate; this type of support was absolutely top-notch, and it really made the project go seamlessly.”

Download the Spy Communications Project Highlight